We take production QA (QUALITY ASSURAN) seriously and follows Strict QC standards

1. Incoming Quality Control

2. In-Process Quality Control

3. Final Quality Control

4. Out-Going Quality Control

Calipers

Hardness tester

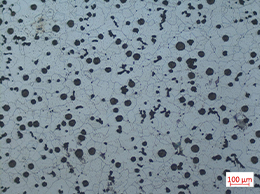

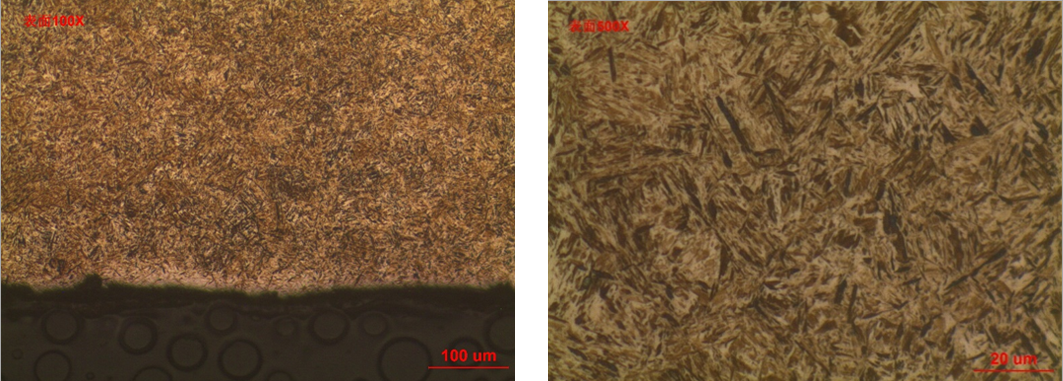

Microstructure test

Wire cutting equipment

Roughness test instruments

Impact test

Tensile test

Surface hardness

Surface roundness

Surface roughness

1# roundness level 2

2# roundness level 2

3# roundness level 2

1# Ball 5

2# Ball 5

3# Ball 5

| Part Number | VB0106L201 | Date | 2022-08-01 | Coiler Type | VB0106L201 | Steel Code | 40Mn2 | |

| Supplier | HT | Operator | ZPF | Adjusted Power | 9400 | Remark | ||

| Heating Temperature | 850°C | Heating Time | 78s | Cooling Time | 40s | Polymer % | 15% | |

| Tempering Temperature | 220°C | Tempering Time | 4h | Water Temperature | Water Pressure | |||

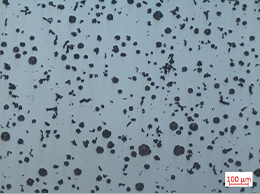

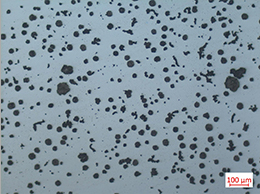

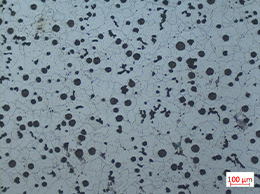

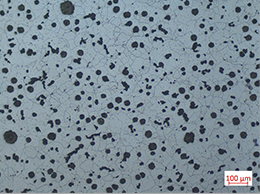

| MagnaFlux Test Result 磁粉探伤 | After Quenching | After Tempering | Microstructure | Microstructure | ||||

| Checked | Good | Checked | Good | |||||

| ok | ok | |||||||

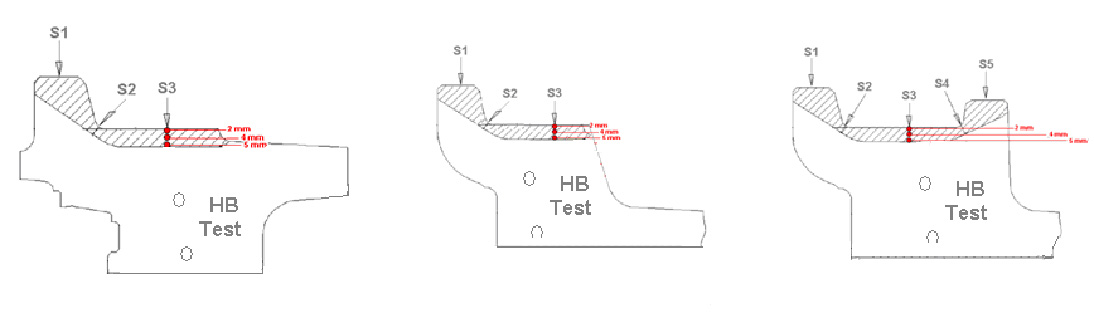

Thickness T= 52 mm, Type C

Specification: S1, S5 depth Min 8 mm, Min.45HRC

S2, S4 depth Min 4 mm, Min.45HRC

S3 depth Min 8 mm, Min.45HRC

Core: Min. 22HRC

| Depth | S1_HRC | S2_HRC | S3_HRC | S4_HRC | S5_HRC | Core _ HRC |

| 1mm | 53 | 52 | 52 | 53 | 52 | 23 |

| 2mm | 51 | 53.5 | 53.5 | 54.5 | 53 | |

| 3mm | 52 | 54 | 53 | 54 | 53 | |

| 4mm | 52 | 48 | 55 | 51 | 52.5 | |

| 5mm | 54 | 43 | 54 | 44 | 54 | |

| 6mm | 54 | 29 | 54 | 34 | 54 | |

| 7mm | 53.5 | 24 | 50 | 27.5 | 53 | |

| 8mm | 52.5 | 24 | 46 | 25.5 | 54 | |

| 9mm | 51.5 | 25 | 30 | 26 | 47.5 | |

| 1mm | 52 | 24 | 25 | 24 | 45.5 |

report-pic1

Section Picture